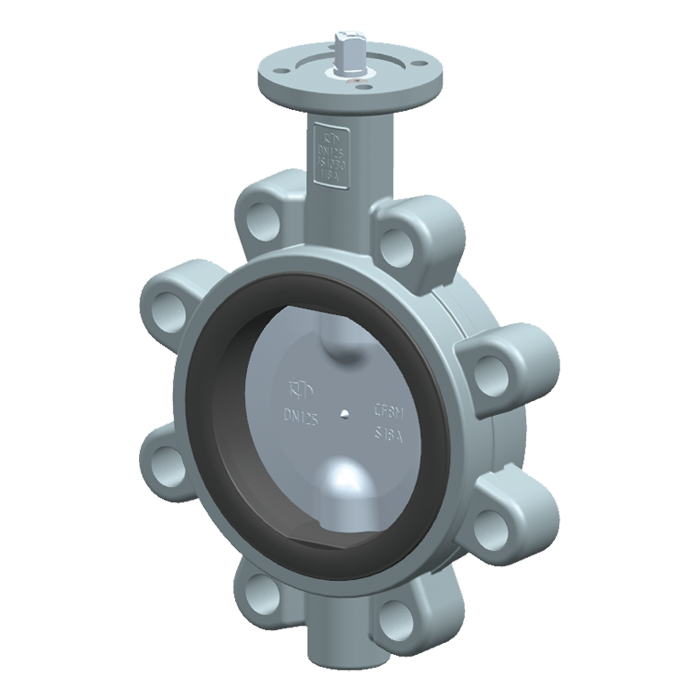

Series A24 lug concentric butterfly valve features a cartridge type seat, streamlined disc and strong stem-to-disc connection for easy use in many industrial applications such as food and beverage, pulp and paper, chemical, mining, water treatment, power plants, etc. Full rated unidirectional dead-end service is achieved by a lip designed in the lug body. FEATURES • ISO5211 top flange together with stem square suitable for direct mounting of actuators

• Stem anti-blowout design keep safety in field use

• Dirtscraper prevents moisture penetrating into the shaft area

• Suitable for high pressure and full vacuum service due to the use of a cartridge seat design

• Full rated unidirectional dead-end service is achieved by a lip designed in the lug body

• No exposed pins or bolts for stem-to-disc connection

• No need for flange gaskets

• No risk of damage to the valve during installation in closed position

• Bubble-tight shut of at full pressure rating

• Large flow capacity and enough strength because of streamline disc design

• Plug with O-ring sealing eliminates any leakage from the stem

| Connection | LUG | | Nominal diameter | DN50-DN2000 | | Operating pressure | 16bar for DN50-DN300,10bar for DN350-DN2000 | Flange

accommodation | DN50-DN300:EN1092 PN10/16,ASME B16.5 Class150,JIS B2239 10K/16K,BS10 Table D/E | | DN350-DN2000:EN1092 PN10/16,ASME B16.5 Class150,BS10 Table D/E | | Face to face | EN558 Series 20, API 609 Table 1 | | Top flange | ISO 5211 | | Tightness check | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40°C to +180°C (Depending on pressure, medium and material) | | Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

| No. | Part name | Material | | 1 | Body | ASTM A536 65-45-12, WCB, CF8M | | 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 | | 3 | Seat | EPDM, NBR, FPM | | 4 | Stem | SS420, SS431 | | 5 | Lower Stem | SS420, SS431 | | 6 | Retainer | Nylon for DN50-DN300, SS304 for DN350-DN2000 | | 7 | Bearing | RPTFE with Graphite on I.D. | | 8 | Weather seal | NBR | | 9 | Weather seal | NBR | | 10 | Plug | Steel galvanized for DN50-DN300, Cover plate for DN350-DN2000

material same as body with SS304 bolts | | 11 | Screw | SS304 |

| SIZE | A | B | C | D | E | F | d | G | H | J | L | WT(kg) | | DN | INCH | | 50 | 2" | 126 | 78 | 13.5 | 117 | 9 | 50 | 8 | 70 | 31 | 34 | 43 | 2.8 | | 65 | 2 1/2" | 134 | 84 | 13.5 | 131 | 9 | 50 | 8 | 70 | 45 | 36 | 46 | 3.7 | | 80 | 3" | 138 | 92 | 13.5 | 176 | 9 | 50 | 8 | 70 | 64 | 36 | 46 | 5.1 | | 100 | 4" | 167 | 114 | 13.5 | 206 | 11 | 70 | 10 | 90 | 91 | 40 | 52 | 6.9 | | 125 | 5" | 180 | 129 | 17.5 | 236 | 14 | 70 | 10 | 90 | 110 | 44 | 56 | 9.3 | | 150 | 6" | 203 | 144 | 17.5 | 258 | 14 | 70 | 10 | 90 | 146 | 44 | 56 | 10.5 | | 200 | 8" | 228 | 179 | 24.5 | 321 | 17 | 102 | 12 | 125 | 193 | 50 | 60 | 17.4 | | 250 | 10" | 266 | 216 | 25 | 395 | 22 | 102 | 12 | 125 | 241 | 57 | 68 | 28.1 | | 300 | 12" | 291 | 247 | 25 | 461 | 22 | 102 | 12 | 125 | 292 | 66 | 78 | 40 | | 350 | 14" | 332 | 273 | 30 | 511 | 27 | 125 | 14 | 150 | 329 | 62 | 78 | 55 | | 400 | 16" | 363 | 317 | 30 | 580 | 27 | 125 | 14 | 150 | 376 | 84 | 102 | 85 | | 450 | 18" | 397 | 348 | 39 | 630 | 36 | 140 | 18 | 175 | 425 | 94 | 114 | 114 | | 500 | 20" | 425 | 393 | 39 | 700 | 36 | 140 | 18 | 175 | 475 | 110 | 127 | 144 | | 600 | 24" | 498 | 453 | 49 | 823 | 46 | 165 | 22 | 210 | 573 | 120 | 154 | 227 | | 700 | 28" | 626 | 531 | 90 | 928 | 63.1 | 254 | 18 | 300 | 674 | 54 | 165 | 342 | | 750 | 30" | 660 | 564 | 90 | 984 | 63.1 | 254 | 18 | 300 | 727 | 54 | 165 | 400 | | 800 | 32" | 666 | 601 | 90 | 1061 | 63.1 | 254 | 18 | 300 | 771 | 60 | 190 | 485 | | 900 | 36" | 722 | 660 | 110 | 1170 | 74.7 | 254 | 18 | 300 | 839 | 60 | 203 | 605 | | 1000 | 40" | 806 | 728 | 120 | 1290 | 83.7 | 298 | 22 | 350 | 939 | 60 | 216 | 776 | | 1100 | 44" | 826 | 771 | 140 | 1404 | 94.7 | 298 | 22 | 350 | 1036 | 50 | 255 | 985 | | 1200 | 48" | 941 | 874 | 150 | 1511 | 104.7 | 298 | 22 | 350 | 1137 | 62 | 276 | 1190 | | 1400 | 56" | 1000 | 940 | 175 | 1685 | 139.9 | 356 | 32 | 415 | 1351 | 62 | 279 | 1380 | | 1600 | 64" | 1155 | 1085 | 195 | 1930 | 160 | 356 | 32 | 415 | 1548 | 65 | 318 | 2054 | | 1800 | 72" | 1200 | 1170 | 195 | 2170 | 174.5 | 406 | 39 | 475 | 1703 | 70 | 356 | 3075 | | 2000 | 80" | 1363 | 1360 | 245 | 2345 | 199 | 406 | 39 | 475 | 1938 | 75 | 406 | 4500 |

| Connection | LUG | | Nominal diameter | DN50-DN2000 | | Operating pressure | 16bar for DN50-DN300,10bar for DN350-DN2000 | Flange

accommodation | DN50-DN300:EN1092 PN10/16,ASME B16.5 Class150,JIS B2239 10K/16K,BS10 Table D/E | | DN350-DN2000:EN1092 PN10/16,ASME B16.5 Class150,BS10 Table D/E | | Face to face | EN558 Series 20, API 609 Table 1 | | Top flange | ISO 5211 | | Tightness check | ISO 5208 Category 3, API 598 Table 5 | | Temperature range | -40°C to +180°C (Depending on pressure, medium and material) | | Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

Series A24 lug concentric butterfly valve features a cartridge type seat, streamlined disc and strong stem-to-disc connection for easy use in many industrial applications such as food and beverage, pulp and paper, chemical, mining, water treatment, power plants, etc. Full rated unidirectional dead-end service is achieved by a lip designed in the lug body. FEATURES • ISO5211 top flange together with stem square suitable for direct mounting of actuators

• Stem anti-blowout design keep safety in field use

• Dirtscraper prevents moisture penetrating into the shaft area

• Suitable for high pressure and full vacuum service due to the use of a cartridge seat design

• Full rated unidirectional dead-end service is achieved by a lip designed in the lug body

• No exposed pins or bolts for stem-to-disc connection

• No need for flange gaskets

• No risk of damage to the valve during installation in closed position

• Bubble-tight shut of at full pressure rating

• Large flow capacity and enough strength because of streamline disc design

• Plug with O-ring sealing eliminates any leakage from the stem

| No. | Part name | Material | | 1 | Body | ASTM A536 65-45-12, WCB, CF8M | | 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 | | 3 | Seat | EPDM, NBR, FPM | | 4 | Stem | SS420, SS431 | | 5 | Lower Stem | SS420, SS431 | | 6 | Retainer | Nylon for DN50-DN300, SS304 for DN350-DN2000 | | 7 | Bearing | RPTFE with Graphite on I.D. | | 8 | Weather seal | NBR | | 9 | Weather seal | NBR | | 10 | Plug | Steel galvanized for DN50-DN300, Cover plate for DN350-DN2000

material same as body with SS304 bolts | | 11 | Screw | SS304 |

| SIZE | A | B | C | D | E | F | d | G | H | J | L | WT(kg) | | DN | INCH | | 50 | 2" | 126 | 78 | 13.5 | 117 | 9 | 50 | 8 | 70 | 31 | 34 | 43 | 2.8 | | 65 | 2 1/2" | 134 | 84 | 13.5 | 131 | 9 | 50 | 8 | 70 | 45 | 36 | 46 | 3.7 | | 80 | 3" | 138 | 92 | 13.5 | 176 | 9 | 50 | 8 | 70 | 64 | 36 | 46 | 5.1 | | 100 | 4" | 167 | 114 | 13.5 | 206 | 11 | 70 | 10 | 90 | 91 | 40 | 52 | 6.9 | | 125 | 5" | 180 | 129 | 17.5 | 236 | 14 | 70 | 10 | 90 | 110 | 44 | 56 | 9.3 | | 150 | 6" | 203 | 144 | 17.5 | 258 | 14 | 70 | 10 | 90 | 146 | 44 | 56 | 10.5 | | 200 | 8" | 228 | 179 | 24.5 | 321 | 17 | 102 | 12 | 125 | 193 | 50 | 60 | 17.4 | | 250 | 10" | 266 | 216 | 25 | 395 | 22 | 102 | 12 | 125 | 241 | 57 | 68 | 28.1 | | 300 | 12" | 291 | 247 | 25 | 461 | 22 | 102 | 12 | 125 | 292 | 66 | 78 | 40 | | 350 | 14" | 332 | 273 | 30 | 511 | 27 | 125 | 14 | 150 | 329 | 62 | 78 | 55 | | 400 | 16" | 363 | 317 | 30 | 580 | 27 | 125 | 14 | 150 | 376 | 84 | 102 | 85 | | 450 | 18" | 397 | 348 | 39 | 630 | 36 | 140 | 18 | 175 | 425 | 94 | 114 | 114 | | 500 | 20" | 425 | 393 | 39 | 700 | 36 | 140 | 18 | 175 | 475 | 110 | 127 | 144 | | 600 | 24" | 498 | 453 | 49 | 823 | 46 | 165 | 22 | 210 | 573 | 120 | 154 | 227 | | 700 | 28" | 626 | 531 | 90 | 928 | 63.1 | 254 | 18 | 300 | 674 | 54 | 165 | 342 | | 750 | 30" | 660 | 564 | 90 | 984 | 63.1 | 254 | 18 | 300 | 727 | 54 | 165 | 400 | | 800 | 32" | 666 | 601 | 90 | 1061 | 63.1 | 254 | 18 | 300 | 771 | 60 | 190 | 485 | | 900 | 36" | 722 | 660 | 110 | 1170 | 74.7 | 254 | 18 | 300 | 839 | 60 | 203 | 605 | | 1000 | 40" | 806 | 728 | 120 | 1290 | 83.7 | 298 | 22 | 350 | 939 | 60 | 216 | 776 | | 1100 | 44" | 826 | 771 | 140 | 1404 | 94.7 | 298 | 22 | 350 | 1036 | 50 | 255 | 985 | | 1200 | 48" | 941 | 874 | 150 | 1511 | 104.7 | 298 | 22 | 350 | 1137 | 62 | 276 | 1190 | | 1400 | 56" | 1000 | 940 | 175 | 1685 | 139.9 | 356 | 32 | 415 | 1351 | 62 | 279 | 1380 | | 1600 | 64" | 1155 | 1085 | 195 | 1930 | 160 | 356 | 32 | 415 | 1548 | 65 | 318 | 2054 | | 1800 | 72" | 1200 | 1170 | 195 | 2170 | 174.5 | 406 | 39 | 475 | 1703 | 70 | 356 | 3075 | | 2000 | 80" | 1363 | 1360 | 245 | 2345 | 199 | 406 | 39 | 475 | 1938 | 75 | 406 | 4500 |

|

Lug Concentric Butterfly Valves ★★★★

Lug Concentric Butterfly Valves ★★★★